How AI is Optimizing Parts Manufacturing Processes

11x bet login, india24bet login, sky fair:In today’s competitive manufacturing landscape, efficiency is the name of the game. Companies are constantly striving to find ways to optimize their processes, reduce costs, and improve quality. One of the most promising technologies to emerge in recent years that is revolutionizing parts manufacturing processes is Artificial Intelligence (AI).

AI is being used to optimize every step of the manufacturing process, from design and prototyping to production and quality control. By leveraging AI technology, manufacturers can streamline their operations, reduce waste, increase productivity, and ultimately, deliver better products to their customers.

Here’s how AI is transforming parts manufacturing processes:

1. Design Optimization:

AI-powered algorithms can analyze vast amounts of data to optimize the design of parts for manufacturability. By considering factors such as material properties, production processes, and cost constraints, AI can help designers create parts that are easier and more cost-effective to manufacture.

2. Production Planning:

AI can help manufacturers optimize their production schedules by taking into account factors such as machine availability, order priorities, and lead times. By intelligently scheduling production runs, manufacturers can reduce idle time, minimize setup costs, and improve overall efficiency.

3. Predictive Maintenance:

AI can predict when machines are likely to fail based on data from sensors and historical maintenance records. By proactively scheduling maintenance, manufacturers can avoid costly downtime and keep their production lines running smoothly.

4. Quality Control:

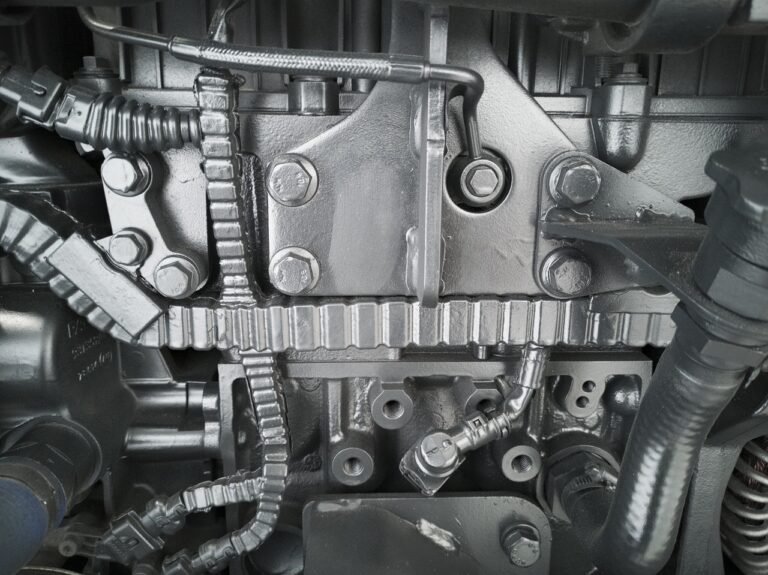

AI-powered image recognition technology can inspect parts for defects with incredible accuracy. By automatically detecting flaws such as cracks, warping, or surface imperfections, manufacturers can ensure that only high-quality parts make it to the customer.

5. Supply Chain Optimization:

AI can analyze supply chain data to optimize inventory levels, reduce lead times, and identify cost-saving opportunities. By optimizing the supply chain, manufacturers can ensure that they have the right parts in the right place at the right time.

6. Energy Efficiency:

AI can optimize energy usage in manufacturing facilities by analyzing data from sensors, weather forecasts, and production schedules. By minimizing energy consumption during peak hours and optimizing equipment utilization, manufacturers can reduce their carbon footprint and lower operating costs.

Overall, AI is revolutionizing parts manufacturing processes by enabling manufacturers to operate more efficiently, reduce costs, and deliver better products to their customers. By embracing AI technology, manufacturers can stay ahead of the competition and thrive in the digital age.

—

FAQs

Q: What are the benefits of using AI in parts manufacturing processes?

A: The benefits of using AI in parts manufacturing processes include improved efficiency, reduced costs, increased productivity, better quality control, and enhanced supply chain optimization.

Q: Is AI expensive to implement in manufacturing?

A: While implementing AI technology can require upfront investment, the long-term benefits far outweigh the costs. By improving efficiency and reducing waste, AI can help manufacturers save money in the long run.

Q: How can manufacturers get started with AI?

A: Manufacturers can start by assessing their current processes and identifying areas where AI can be most beneficial. They can then work with AI vendors or consultants to develop and implement AI solutions tailored to their specific needs.

Q: Is AI technology mature enough to be reliable in manufacturing processes?

A: Yes, AI technology has matured significantly in recent years and is now being successfully used in a wide range of manufacturing applications. With the right implementation and training, AI can deliver reliable results and help manufacturers stay competitive in today’s fast-paced market.