Discovering the Best Rice Milling Machine in the World: A Complete Guide for Modern Millers

Rice is one of the most consumed grains globally, feeding over half of the world’s population daily. With the increasing demand for high-quality rice, the milling industry has evolved to incorporate advanced machinery that ensures efficient, hygienic, and high-yield production. Among all technological innovations, the Best Rice Milling Machine In The World stands out for its ability to deliver superior performance, precision, and reliability. In this blog, we explore what makes a rice milling machine the best, the features to look for, and why global rice millers are upgrading to next-generation equipment.

What is a Rice Milling Machine?

A rice milling machine is an automated system designed to process paddy into white or polished rice. It performs a series of operations such as pre-cleaning, dehusking, separating, whitening, polishing, grading, sorting, and packing. The goal is to produce market-ready rice that meets international quality standards. The best rice milling machines in the world are those that integrate all these functions seamlessly while maximizing yield and minimizing grain breakage.

Why Milling Quality Matters

Rice milling is not just about turning paddy into white rice. It’s about preserving the nutritional value, maintaining grain integrity, and achieving a visually appealing product. The best rice milling machines ensure:

-

Low broken rice percentage

-

Uniform grain size and color

-

Hygienic processing

-

High throughput with consistent quality

Machines that fail to meet these criteria can affect profitability and damage brand reputation, especially in competitive markets.

Features of the Best Rice Milling Machine in the World

High Efficiency

Top-tier machines can process several tons of rice per hour while maintaining quality. Efficiency ensures millers can meet growing market demands without delays.

Advanced Automation

Modern rice milling machines are fully automated and equipped with digital control panels, allowing operators to monitor and adjust the milling process with minimal manual input.

Multi-Stage Processing

The best machines integrate multiple stages in a single system, including cleaning, dehusking, whitening, polishing, grading, and sorting. This reduces dependency on standalone machines and streamlines operations.

Minimal Grain Breakage

Premium machines are engineered to reduce stress on rice grains during dehusking and polishing, resulting in higher yields of full-grain white rice.

Energy Efficiency

World-class milling machines are designed to be energy-efficient, reducing power consumption and operational costs over time.

Customization Options

Top machines allow millers to adjust settings based on rice type, moisture level, and desired finish, making them versatile for different markets.

Durable Construction

Machines made from stainless steel or food-grade materials last longer, resist corrosion, and maintain hygiene during continuous operation.

Safety Features

Built-in safety mechanisms like overload protection, emergency stop, and dust control help ensure worker safety and maintain a clean environment.

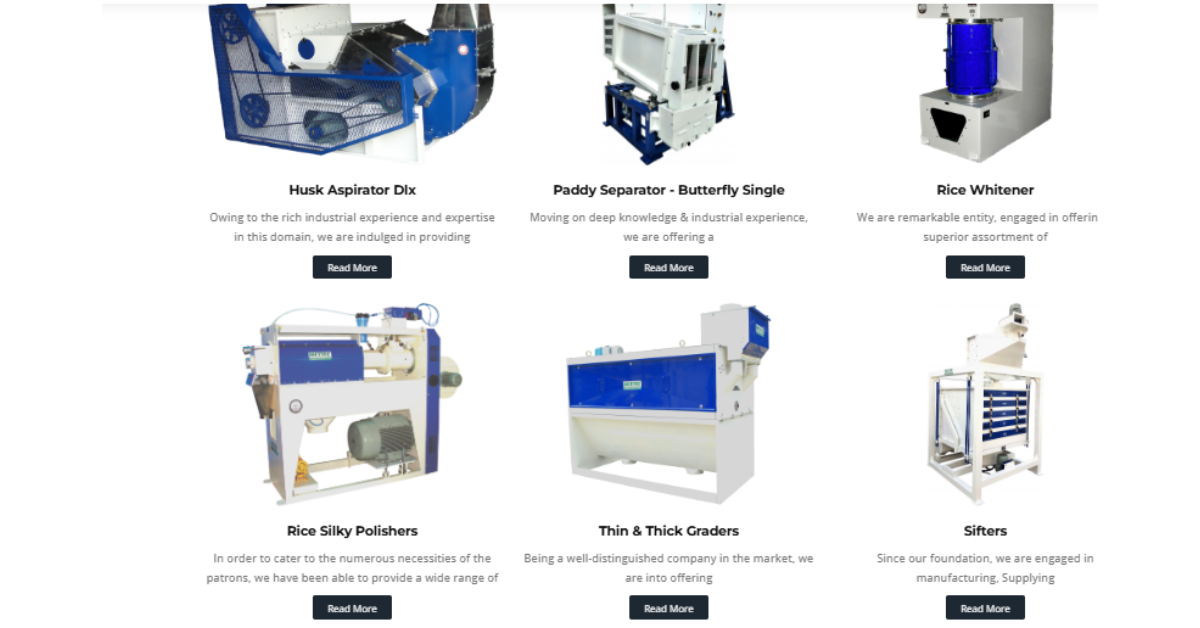

Components of the World’s Best Rice Milling Machine

A high-performance rice milling system includes several integrated machines working in harmony:

1. Pre-Cleaner

Removes dust, straw, stones, and other impurities before milling begins. It protects downstream equipment and ensures clean raw material input.

2. Dehusker

Removes the outer husk from the paddy using rubber rollers. Premium machines maintain precise pressure to avoid grain breakage.

3. Paddy Separator

Separates unhusked grains from brown rice. The best separators ensure nearly complete separation for maximum efficiency.

4. Whitening Machine

Removes the bran layers to produce white rice. Top whitening machines maintain texture and reduce heat generation, preserving rice quality.

5. Polisher

Polishes white rice to enhance its luster. World-class polishers provide a glossy finish without compromising on grain structure.

6. Grader

Sorts grains based on size. Uniform grain size increases market value and consumer satisfaction.

7. Color Sorter

Uses high-speed cameras and AI to detect and remove discolored or defective grains. This results in premium-quality, visually uniform rice.

8. Packing Machine

Automatically fills and seals rice in bags, ensuring accurate weight and clean packaging for retail or bulk sales.

Best Brands Leading the Rice Milling Industry

Several companies have established themselves as leaders in the global rice milling market. The most renowned manufacturers include:

Satake (Japan)

Known for innovation and high-precision equipment, Satake machines are widely used in large-scale rice mills worldwide.

Bühler (Switzerland)

Bühler is a trusted name for grain processing. Their rice mills combine Swiss engineering with cutting-edge automation.

Ricetec Machinery (India)

Ricetec has built a strong reputation for delivering world-class rice milling solutions tailored to both domestic and international markets. With a strong focus on quality, customization, and efficiency, Ricetec machines are among the best rice milling machines in the world.

Why Ricetec Machinery Stands Out

Ricetec Machinery offers a wide range of high-performance rice milling equipment designed for every scale of operation. Here’s why Ricetec is considered among the top:

-

Fully automated systems with intelligent control features

-

High-capacity machines with low breakage and energy consumption

-

Complete turnkey solutions including layout design, installation, and training

-

International-grade quality and reliability

-

Custom configurations for various rice types and regional requirements

Whether you’re a new entrepreneur or an established miller, Ricetec Machinery provides future-ready solutions that help scale your operations effectively.

How to Choose the Best Rice Milling Machine for Your Needs

Choosing the right machine depends on several factors:

Milling Capacity

Assess how much rice you need to process daily or monthly. Choose a machine that matches your throughput without overloading.

Level of Automation

Automated systems are ideal for large-scale production, while semi-automatic machines may suit smaller mills with lower budgets.

Rice Type

Different rice types—such as basmati, long grain, and parboiled—require specific machine settings. Choose a machine that offers the flexibility to handle multiple varieties.

Budget

While the best machines are not the cheapest, they offer a better return on investment due to higher yield, quality, and efficiency.

After-Sales Support

Choose a manufacturer that offers installation, training, spare parts, and service support to ensure smooth operation.

Maintenance Tips for Optimal Machine Performance

Even the best machines need regular care to operate at peak performance:

-

Clean equipment regularly to remove dust, husk, and bran buildup

-

Check moving parts and belts for wear and replace them as needed

-

Monitor motor and electrical components periodically

-

Lubricate critical components based on the manufacturer’s recommendations

-

Schedule professional maintenance inspections at least twice a year

Frequently Asked Questions (FAQ)

What makes a rice milling machine the best in the world?

The best rice milling machines offer high efficiency, full automation, minimal grain breakage, superior quality output, energy efficiency, and durable construction.

How much does the best rice milling machine cost?

Prices vary depending on capacity and features. A high-end automated system may cost more initially but provides better returns over time due to lower wastage and higher output.

Can Ricetec Machinery machines be used for export-quality rice?

Yes, Ricetec machines are designed to meet international quality standards and are used by exporters to process high-grade rice for global markets.

Is it possible to customize the rice milling machine?

Absolutely. The best manufacturers, including Ricetec, offer machines that can be customized based on grain type, capacity, and desired finish.

How long does installation take?

Depending on the complexity and scale, installation can take a few days to several weeks. Ricetec provides complete support, including layout design, installation, and commissioning.

Conclusion

The search for the Best Rice Milling Machine in the World leads to machines that combine technology, efficiency, and reliability. Choosing the right system can drastically improve your rice mill’s productivity, quality, and profitability. Leading manufacturers like Ricetec Machinery provide all-in-one solutions that include cleaning, dehusking, polishing, grading, and packaging—delivering consistent results every time. Whether you’re modernizing your plant or starting from scratch, investing in a world-class rice milling machine is a critical step toward long-term success in the rice processing industry.